It pays to know not only where equipment is, but what and how it’s doing. iOPS (Intelligent Operations Performance Systems) from JBT monitors gate equipment operations, ground support equipment (GSE) and baggage handling systems. The platform can provide actionable information on the status, performance and faults of the equipment.

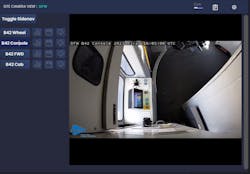

Monitoring various systems, iOPS gives operations a go or no go signal. Green means the equipment is ready and usable, while a red X indicates equipment is out for maintenance or inoperable. Green with a red box means there’s an alarm that needs looking into.

Most commonly, John Thompson, JBT Vice President of Global Gate Equipment Sales, said customers use iOPS to monitor GSE for common alarms and failures, turn performance and operational statistics.

Looking specifically at the benefits of using iOPS with passenger boarding bridges (PBBs), Thompson said, “iOPS gives real-time, actionable information about the PBBs anywhere you have access to the internet. There is no need to be on site at the equipment to be able to troubleshoot issues. This is the real advantage to iOPS.”

Without iOPS, Thompson said operators need to be at the PBB to find out what the issues are and try to diagnose them through the limited human machine interface (HMI) screen.

“Having information at your fingertips (at your computer or on your phone) about how a bridge is operating can save valuable time and resources,” he continued. “Just picture an international flight has landed at JFK and half of those passengers need to get through customs to make their next flight, and the PBB will not move because someone pressed an E-stop. Something so simple could be fixed in seconds and could stop a flight from being delayed 30 minutes or more.”

iOPS can be used to ensure the gate and boarding bridge are ready for the aircraft turn, monitor how the boarding bridge is being operated, how long the docking process is taking, and if there are any safety or training concerns. Using the technology to manage personnel, fleet and operations, Thompson said the goal is to improve operations, reduce equipment downtime and save money.

Customers who use iOPS with boarding bridges include airlines, airports (Thompson said maintenance departments love the ability to remotely monitor their equipment.) and third-party maintenance providers, as well as ground handlers, cargo handlers and military.

To use iOPS with a boarding bridge, the boarding bridge doesn’t have to be new. Thompson said passenger boarding bridges can be upgraded to take advantage of new technologies to help improve performance and operations.

Customers who use iOPS for boarding bridges also use the technology to monitor the GSE, including ground power units (GPUs) and pre-conditioned air units (PCAs), that attach to the boarding bridge. Mobile GSE commonly used with iOPS includes push-back tractors, deicers and other mobile equipment, along with rooftop units and visual docking guidance systems.

To use iOPS with a passenger boarding bridge, iOPS can be installed and monitored through cell service or hardwired – if the boarding bridge has communication lines back to the building.

“Either way, the installation is simple and can be accomplished between flights on an active gate,” Thompson said.

What can be monitored?

“Basically, we monitor every point that is gathered into the PLC (programmable logic controllers) of the PBB,” he said.

According to Thompson, this could be hundreds of points monitored and displayed – to only a few including the PBB docking status and preconditioned air unit (PCA) on/off status.

Also monitored are site-specific alarms based on customer needs.

“We can set up any alerts of end-users and display them how they choose,” he said. “iOPS can be very custom and site specific. A good example of a custom alert build is one we call ‘PCA not meeting performance.’ This is a notification that the PCA is operational, but not meeting design condition.”

iOPS also can be used to monitor how long the docking process is taking, and an add-on feature that uses cameras and stores video footage for seven days can be used to identify and point out training or safety concerns.

“With the iOPS AI Vision systems, we are able to detect when safety items are not being used, which could cost hundreds of thousands of dollars in damage,” Thompson said.

Lastly, iOPS can also be used to contact JBT for equipment parts and service.