Just as robotics and imaging has helped to enable minimally invasive surgeries on patients that allow them to recover faster, these technologies also are enabling less invasive inspection and repair of jet engines on wing to reduce downtime.

Meet GE Aerospace’s Sensiworm (Soft ElectroNics Skin-Innervated Robotic Worm), a highly intelligent, acutely sensitive soft robot that could serve as extra sets of eyes and ears for aerospace service operators inside the engine. Today, these operators use highly advanced inspection instruments like a video borescope that provide extremely valuable inspection data but are limited in overall turbine coverage because of factors such as gravity that can cause the tip to naturally settle when not braced against a structure within the engine. Deploying self-propelling, compliant robots like Sensiworm would give operators virtually unfettered access in the future to perform inspections without having to disassemble the engine.

“With mini-robot companions like Sensiworm, service operators would have multiple additional sets of eyes and ears to perform on-wing inspections,” said Deepak Trivedi, Principal Robotics Engineer, GE Aerospace Research. “With their soft, compliant design, they could inspect every inch of jet engine transmitting live video and real-time data about the condition of parts that operators typically check. Sensiworm can even measure the thickness of thermal barrier coatings on parts that are applied to protect the parts from heat.”

“Currently, our demonstrations have primarily been focused on the inspection of engines,” Trivedi added. “But we’re developing new capabilities that would allow these robots to execute repair once they find a defect as well.”

GE Aerospace’s Sensiworm robot has been developed with funding and support through SEMI Flex Tech, an industry-led public/private partnership focused on advancing innovative hybrid electronics developments like Sensiworm. The program is funded by the US Army Research Lab. The GE team also is partnered with Binghamton University, which is home to a world-class Center for Advanced Microelectronics Manufacturing (CAMM), and UES, Inc, an Ohio-based R&D organization that works often with commercial and military partners on advanced technologies in multiple areas that include aerospace and electronics research.

Gity Samadi, PhD, Director of R&D Programs, SEMI Global Headquarters, said, “This project demonstrates our commitment to progress in Flexible Hybrid Electronics and beyond. It embodies the principles that drive our R&D funding consortium, mitigating risks for breakthrough technology that propels industry advancement.”

“Working with GE allows our research team to help move ideas from the lab into the real world, which is exciting for me and my students alike,” said Mark Poliks, SUNY Distinguished Professor and Director of the Center for Advanced Microelectronics Manufacturing at Binghamton University. “We look forward to seeing Sensiworm in action and to future collaborations with our industry partners in New York State and beyond. There are so many ways we can use flexible hybrid electronics to improve human health and safety.”

“Our partnership with SEMI Flex Tech, Binghamton University, and UES has provided an incredible platform to accelerate the development of our Sensiworm robot,” Trivedi said. “The programs they support are critically important in helping private industry deploy new technologies from the lab into their business operations. We still have more developments ahead with Sensiworm. But the early results from our demonstrations show that we indeed have real ‘skin in the game’ when it comes to deploying future robotic solutions in aircraft engine services.”

Trivedi explained that innovative in-situ and highly intelligent robotic platforms like Sensiworm are a key technical capability required for performing more robust on-wing inspections in the future. This can reduce unnecessary removals and downtime and enable faster turnaround times to keep engines at peak operational availability.

About Sensiworm

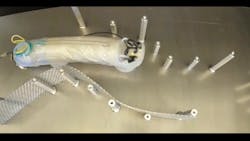

Sensiworm is a highly compliant soft robot that resembles an inchworm. It is self-contained, with on- board power, compute, and pressure resources. The team has demonstrated its ability to move easily on and around the various crevasses and curves of jet engine parts to look for cracks and corrosion. In other lab scale demonstrations, Sensiworm also has been shown to accurately inspect and measure the thickness of thermal barrier coatings on engine parts to determine if parts are maintaining the proper thickness.

Sensiworm could help further expand coverage and inspection capabilities inside an engine vs. the state-of-the-art borescope technologies presently used. Sensiworm can be deployed through the turbine inlet or exhaust of an engine and provide coverage of a much larger swath of the turbine that would otherwise be missed using traditional borescopes, bespoke robotic devices, or snake platforms utilizing conventional port access points. The goal is to provide on-wing service personnel with multiple sets of trusted eyes and ears inside the engine that have the ability to inspect and repair critical areas of the engine.

About GE Aerospace Research

GE Aerospace Research is the central hub of innovation for GE Aerospace and one of the industry’s most diversified and global research and development operations. The lab, with research facilities in the US (Niskayuna, NY) and India (Bengaluru), have more 650 researchers with expertise across virtually every scientific and engineering discipline. They have teams leading a range of advanced technology developments in in materials science, propulsion, power electronics, avionics thermal management, 3D manufacturing and more to expand the frontiers of more sustainable air travel in skies and beyond.

This material is based on research sponsored by Army Research Laboratory under agreement number W911NF-19-2-0345. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation thereon.

The views and conclusions contained herein are those of the authors and should not be interpreted as necessarily representing the official policies or endorsements, either expressed or implied, of Army Research Laboratory ( ARL) or the U.S. Government.